Metal Stamping Design Guide Industry leaders in metal stamping follow a set of design formulas to ensure they meet a project s requirements in performance aesthetics and most importantly cost Inside ESI s Metal Stamping Design Guide we ve illustrated these metal stamping best practices and highlight tips to incorporate cost cutting considerations into your part

Inside ESI s Metal Stamping Design Guide we ve illustrated these metal stamping best practices and highlight tips to incorporate cost cutting considerations into your part You ll learn how to 1 Avoid costly errors 2 Know what to expect in terms of costs and lead times 3 Design the highest quality components so your application performs at Stamping Design Manual Collaborative product process development guidelines for high This manual is intended as a practical guide for automotive material engineers product designers specified grade and type For grades 180 and 210 using an interstitial free IF base metal having a carbon content less than 0 01 an effective boron

Metal Stamping Design Guide

Metal Stamping Design Guide

Metal Stamping Design Guide

https://i.pinimg.com/originals/97/82/64/978264588cec9bdddc1ebc69c9ba8c56.jpg

Metal stamping is one of the most cost effective highly efficient accurately repeatable and widely used manufacturing process in the world It s essential to start with the best product designs that ensure optimized part performance quick turnaround high quality and minimized costs

Templates are pre-designed files or files that can be used for various functions. They can conserve time and effort by offering a ready-made format and layout for creating various sort of content. Templates can be used for personal or professional tasks, such as resumes, invites, flyers, newsletters, reports, discussions, and more.

Metal Stamping Design Guide

Metal stamping industries ESI Engineering Specialties Inc

Expulsores De Puente Vs De Resorte Censa Industrial

Metal Stamping The Complete Guide

Carbide Dies Overton Industries

Metal Stamping Tools Swirly Cloud Metal Design Stamp 11mm

China China New Product Metal Stamping Design Guide Fixture Check

https://cdn.thomasnet.com/kc/104/doc/ESI-Metal-Stamping-Design-Guide-v7.pdf

Basic design concepts that improve quality and cut costs Introduction Metal stamping is a complex process that can include a number of metal forming processes blanking punching bending and piercing to name a few

http://www.bokers.com/userfiles/downloads/Bokers_Stamping_Guide.pdf

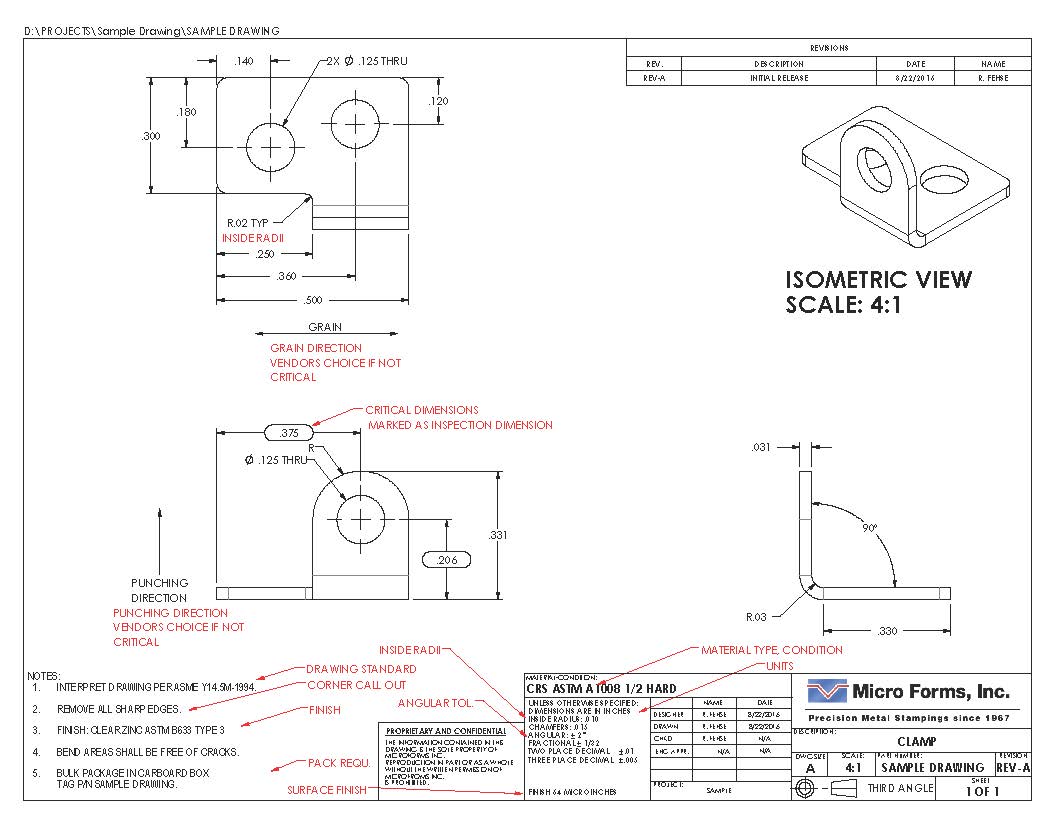

The basics of metal stampings Precision metal stampings are produced by converting flat metal sheet or coil into engineered component parts for manufacturers Parts can be flat and simple or complex profiles

https://www.xometry.com/resources/industry-design-tips/stamping-design-tips/

Metal stamping is a manufacturing process in which coils or flat sheets of material get formed into specific shapes through compression and shearing Stamping encompasses multiple forming techniques such as blanking punching embossing and progressive die stamping to mention just a few

https://larsontool.com/wp-content/uploads/2015/06/larson_design_guide.pdf

Design Guide by Neil Fonger Metal Stamping Design Guidelines Metal Stamping is an economical way of producing quantities of parts that can have many qualities including strength durability wear resistance good conductive properties and stability

https://www.machinemfg.com/metal-stamping-and-die-design-forming/

Looking to learn more about metal stamping and die design forming Look no further than this comprehensive guide from MachineMfg Whether you re a seasoned professional or just starting out in the industry this article has everything you need to know about hole flanging non round hole flanging necking and bulging

The design of a particular metal stamping or precision fabrication is important to its cost The savings in time and money depends on many factors relating to materials quantities tolerances and its overall general design To make your metal stampings and precision fabrications as functional efficient and economical as possible the Form height to thickness ratio To determine the minimum form height for sheet metal use the following formula D 2 5T R see below The height can be less but it required secondary operations and is far more costly Edge Distortion An exaggerated example of edge deformation is pictured in figure A below

Metal stamping is a cold forming manufacturing process that encompasses a broad series of steps for transforming flat metal sheets into unique shapes with features such as bends holes grooves and slots Some of the individual processes that metal stamping manufacturers use include Blanking