Heat Trace Installation Details Electric Heat Trace Installation Guide Good SPDT UL listed mechanical switch Line or ambient sensing NEMA 4X or 7 rated enclosure Rated for 22 amps Better Digital PID control with integrated GFI breaker Has soft start capability to extend run lengths and rated at 30 amps Best

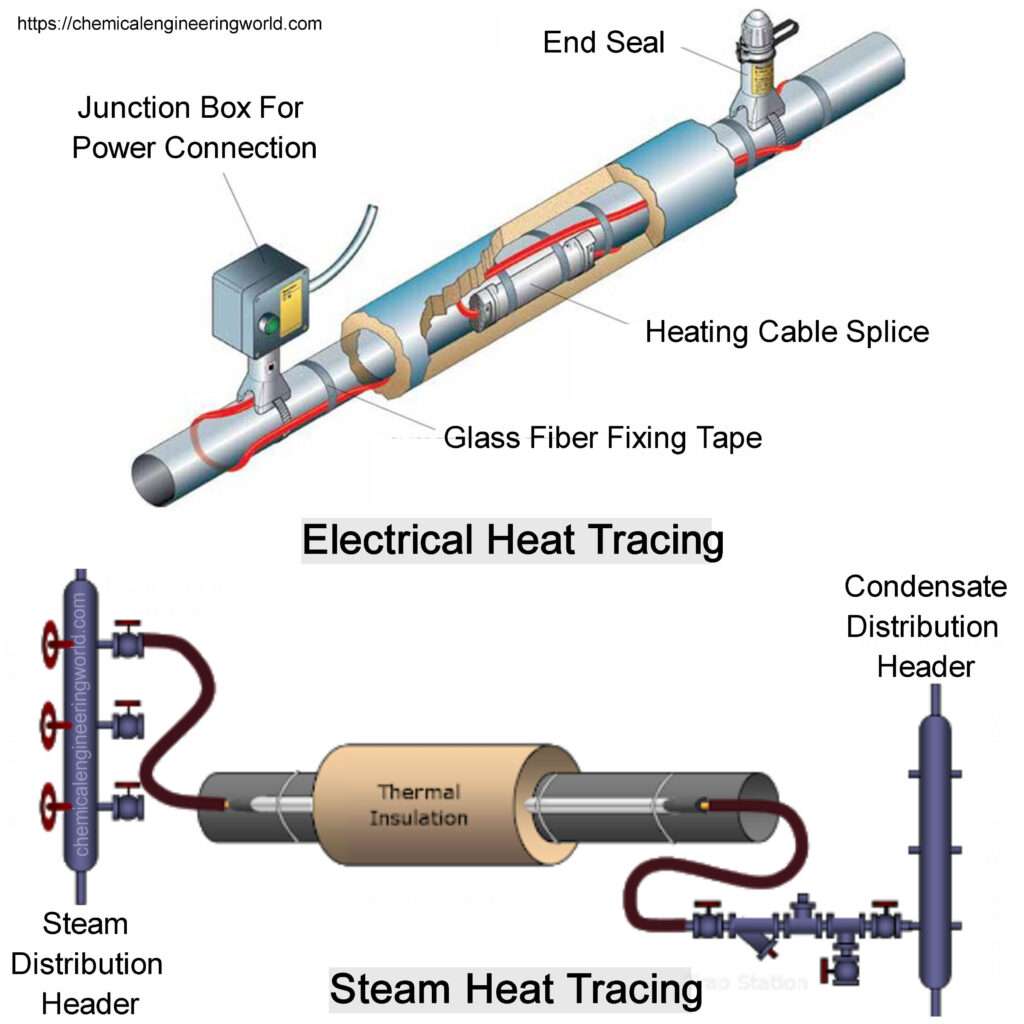

Industrial Heat Tracing Installation and Maintenance Manual For Self Regulating and Power Limiting Heating Cable Systems Important Safeguards and Warnings WARNING FIRE AND SHOCK HAZARD nVent RAYCHEM heat tracing systems must be installed correctly to ensure proper operation and to prevent shock and fire Product Description FLX self regulating heat trace varies its heat output to compensate for the surrounding conditions along the entire length of a circuit Whenever the heat loss of the insulated pipe tank or equipment increases as ambient temperature drops the heat output of the heat trace increases

Heat Trace Installation Details

Heat Trace Installation Details

Heat Trace Installation Details

https://pac-plumbing.com/wp-content/uploads/2020/01/global-electric-heat-tracing-market-scaled.jpg

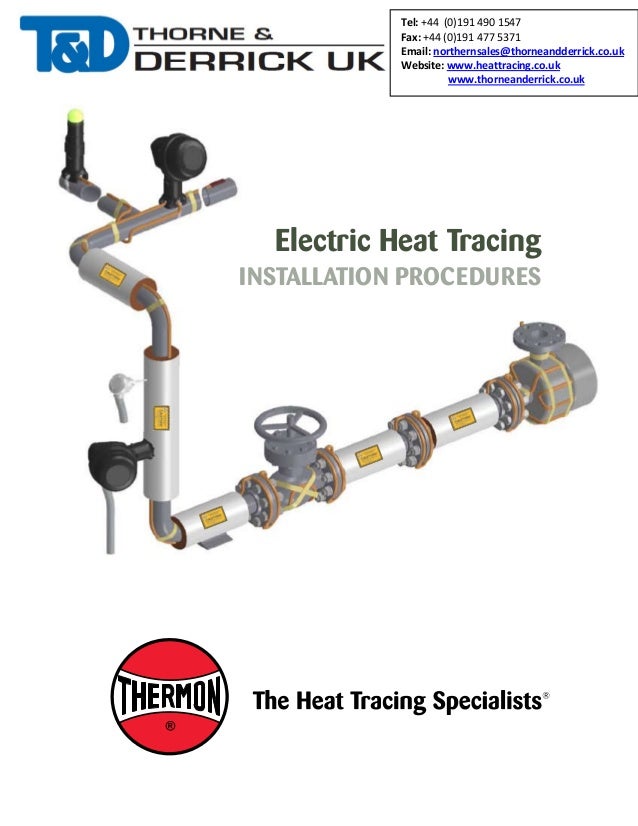

Suggested guidelines for the installation of a Thermon electric heat tracing system Visit us on our website at www thermon for additional details on Hea

Pre-crafted templates use a time-saving option for producing a varied variety of files and files. These pre-designed formats and designs can be utilized for various personal and expert tasks, including resumes, invites, flyers, newsletters, reports, presentations, and more, streamlining the content production process.

Heat Trace Installation Details

Electric Heat Tracing Installation Thermon Manufacturing Co YouTube

Electric Heat Tracing Installation Procedures Thermon Cables

Industrial Heat Tracing Heat Trace Installation In CO WY TX

Electric Heat Tracing System Installation Guide For Petrochemical Plants

Powerblanket Blog Total Temperature Control Solutions

Heat Pump Wiring Diagram Database Wiring Diagram Sample

https://www.powerblanket.com/blog/how-to-install-heat-trace/

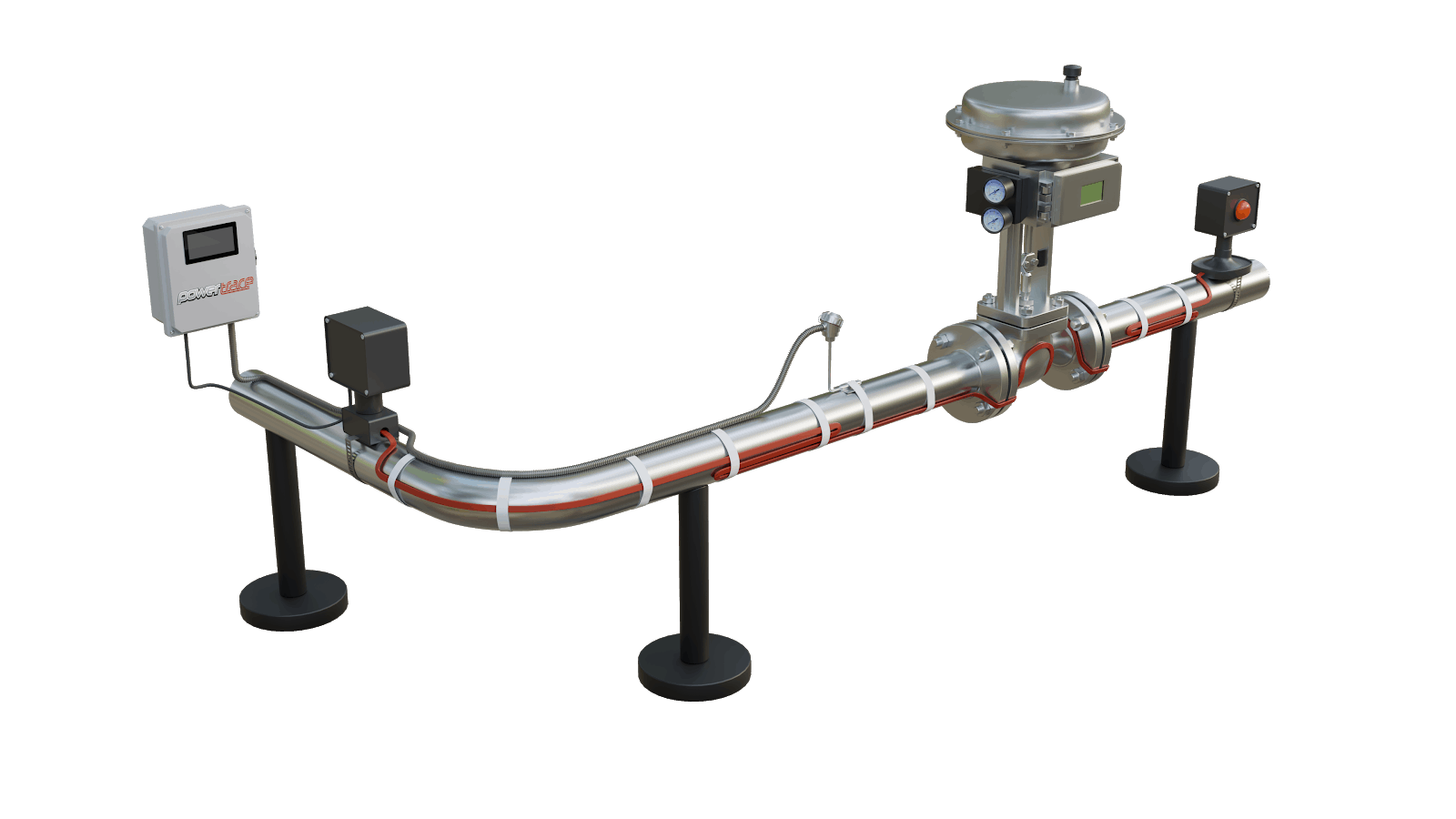

A heat trace system includes Heat tracing cables self regulating heating cables constant watt cables or power limiting cables applied to piping and tanks often secured with fiberglass or aluminum A control panel or thermostat A power connection box to connect power from the breaker Ambient temperature sensor Insulation jacket

https://www.heattracespecialists.com/images/pdf/Other-Products/Industrial-High-Temp-Maintenance/Design-Guide-and-Installation-Details-for-Self-Regulating-Heating-Cable.pdf

The RSCC 2700 self regulating heat ing cable is available with either a tinned copper or stainless steel over shield Factory Mutual approved for use in Class I Division 2 Groups B C and D Class II Division 2 Group G Class III Division 2 areas It is rated for T5 per NEC

https://www.powerblanket.com/blog/guide-to-audit-your-heat-trace-installation-best-practices/

Electric heat trace installations happen in your facility all of the time How do you know that your installation is a good or bad one As winter looms near on all of our calendars how can you know that the system that you have installed should work the way it s supposed to

https://www.emerson.com/documents/commercial-residential/instruction-sheet-easyheat-mi-trace-cable-14035-001-en-1529784.pdf

The following figures show installation details for various typical situations Figures 12 13 show the area of the pipe that is affected by heat losses from items penetrating the insulation such as supports hangers valve yokes etc Heater cable adders can be applied anywhere in this area to compensate for these heat losses

https://www.powerblanket.com/blog/everything-you-need-to-know-about-heat-trace/

Heat trace utilizes electricity and insulation to maintain or increase the temperature of pipes or other vessels replacing any heat lost to outside temperatures A heat trace system protects pipes and tanks from freeze damage while maintaining ideal temperatures to ensure that you never have to sacrifice efficiency to heat loss

The first step in designing a heat trace system is to determine the heat loss from each pipe or tank to be traced Collect the following data for each pipe for tank applications go to page 6 Then fol low the steps below to determine the heat loss Maintenance Temperature T m Minimum Ambient Temperature Ta Location Indoor Outdoor A heat run system includes Heat locating cables self regulating heating cables constant watt cables or power limiting cables applicable in piping and containers often secured with fiberglass or aluminum also carefully trail all the installation instructions

This kit may be installed at temperatures as low as 40 F 40 C For easier installation store above freezing until just before installation For technical support call nVent at 800 545 6258 TOOLS REQUIRED Adjustable wrench Slotted screwdriver Wire strippers Diagonal cutters Utility knife Disposable towel or rag