Aluminum Extrusion Design Guide Some of the most common aluminum alloys used in aluminum extrusion design include Alloy series 1000 These alloys are made up of 99 aluminum Al with no major alloying element additions These alloys are characterized by excellent corrosion resistance high thermal and electrical conductivity and excellent workability

The Aluminum Extrusion Manual has been updated with new previously unpublished content Three new sections have been added or expanded Sustainability Learn some of the ways that the use of extruded components are reducing the environmental impact of buildings and vehicles Fabrication Expanded to include the myriad ways in which aluminum extrusions can be processed after extruding to Download this free aluminum extrusion design guide PDF to learn how to reduce manufacturing costs maximize quality and improve production speeds

Aluminum Extrusion Design Guide

Aluminum Extrusion Design Guide

Aluminum Extrusion Design Guide

https://blog.misumiusa.com/wp-content/uploads/2016/09/IMG_1012.jpg

Design Guide ALUMINUM EXTRUSIONS GENERAL EXTRUSIONS INC Introduction We re here to help luminum extrusions can reduce assembly time and improve compo nent appearance and performance Use these basic design considerations to convert from other processes or create a new aluminum component

Pre-crafted templates use a time-saving option for producing a diverse variety of documents and files. These pre-designed formats and designs can be used for different personal and expert tasks, consisting of resumes, invites, flyers, newsletters, reports, discussions, and more, enhancing the material development process.

Aluminum Extrusion Design Guide

Aluminum Extrusion Design Guide 11 Tips For Designers

84x28 100 Aluminum Extrusion Design Guide Pcb Enclosure Box Electronics

Aluminum Heat Sink Extrusions 260 Shapes Custom

Aluminium Extrusion Manufacturer Extrusion Processing Guide

Full Detailed Design Of The Aluminium Extrusion Die set Featuring An

Aluminium Extrusions Technical Design Guide Extrusi n Tratamiento

https://aec.org/extrusion-design-tips

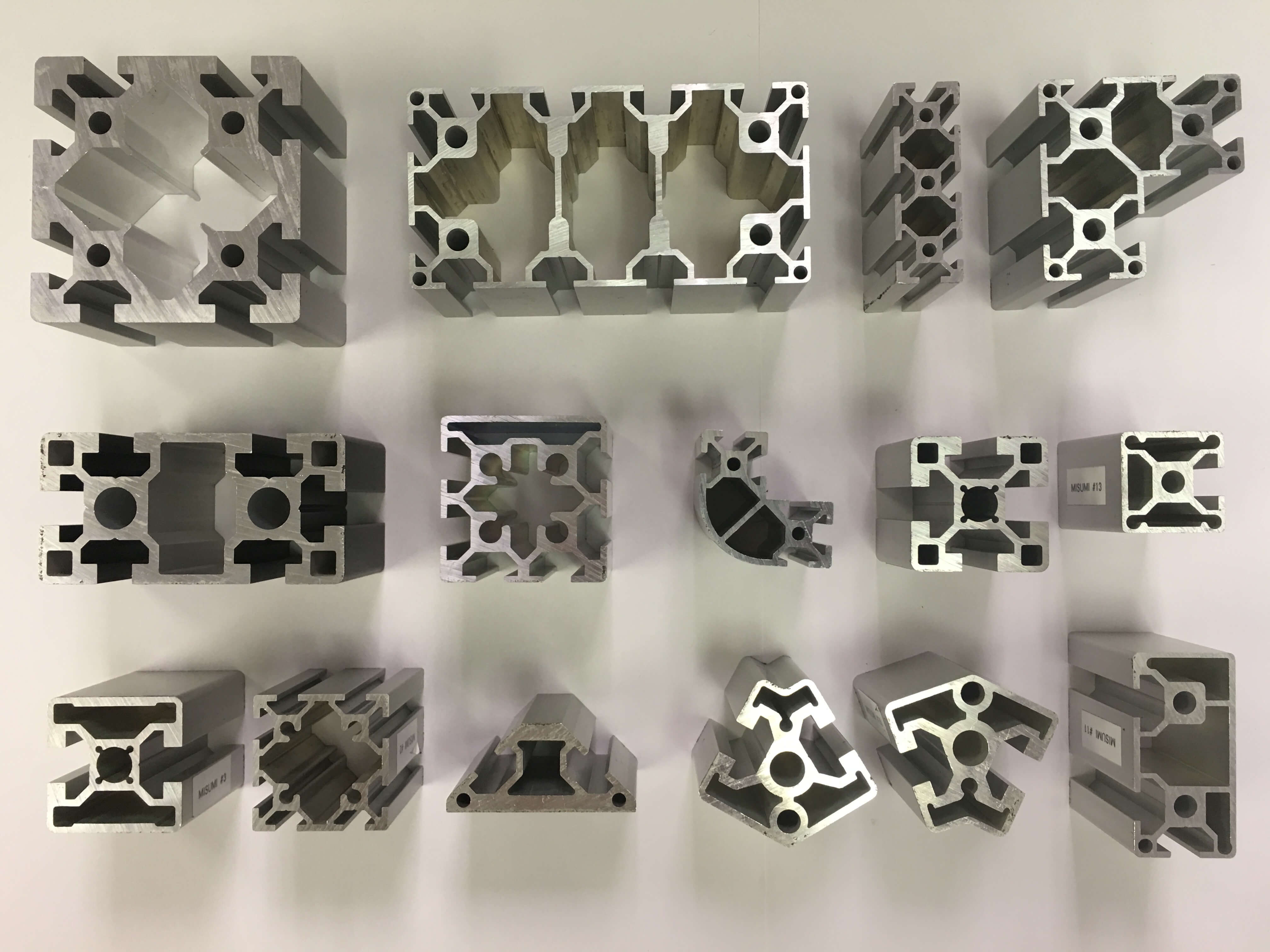

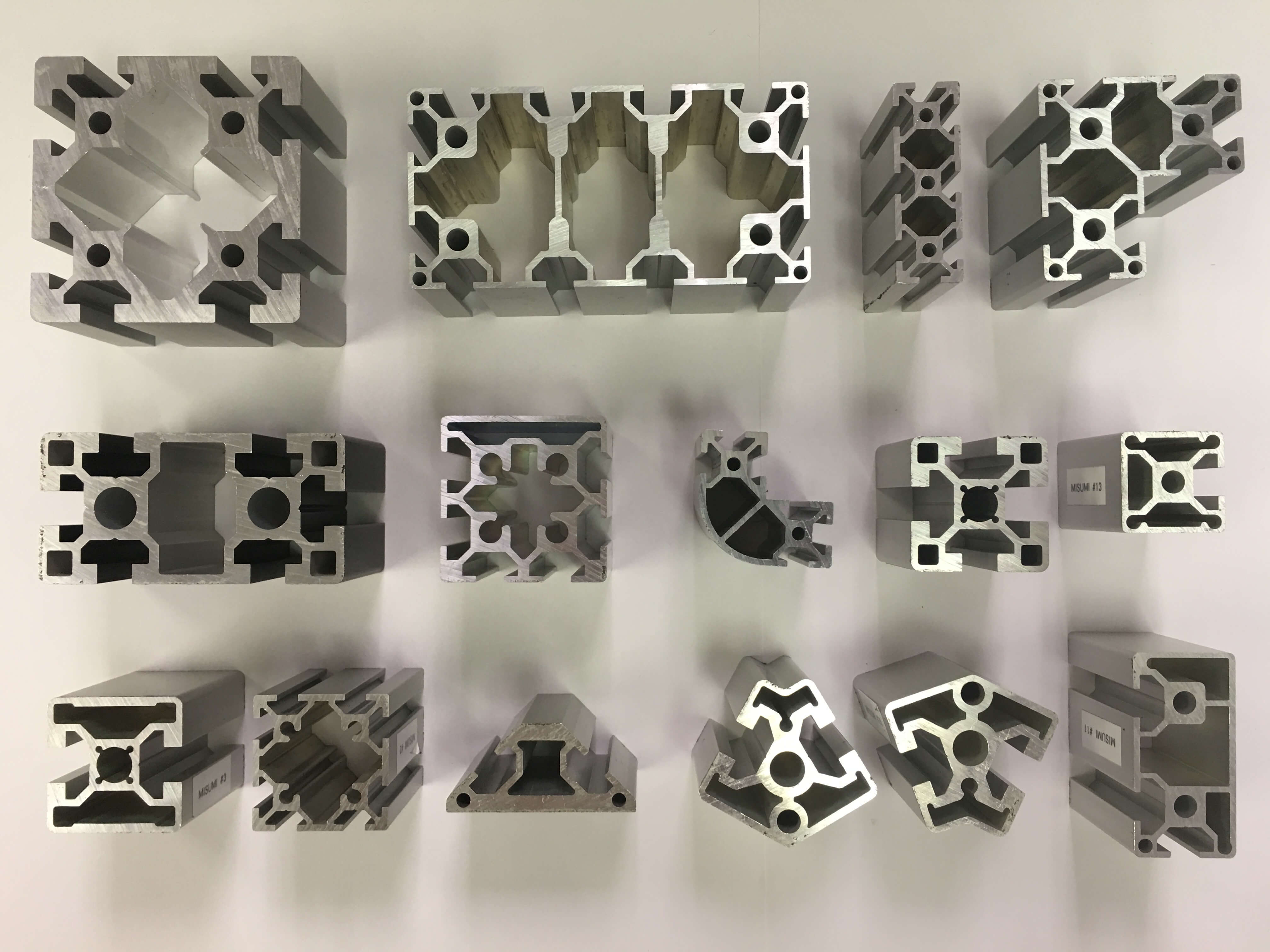

Basically aluminum extrusion allows you to design the shape that best meets your functional structural and aesthetic requirements Extruded shapes are described in three general categories solid hollow and semi hollow Hollow Shapes A hollow shape is simply an extruded shape that completely encloses a void anywhere in its cross section

https://vention.io/resources/guides/t-slot-aluminum-extrusion-structure-design-guide-77

1 Choosing the right extrusion profile 45 x 45 mm Light Duty Extrusion Tabletop Extrusion Calculate the safety factor Calculate bending stresses Calculate buckling strength 2 Choose the right joint configuration 3 Use high strength extrusion systems for demanding applications 4 Structural joint design guide Conclusion

https://aec.org/aluminum-extrusion-manual

Download our updated aluminum extrusions manual to gain an understanding of the extrusion process and design New sections are included for sustainability fabrication microstructure

https://tri-stateal.com/resources/extrusion-guide/

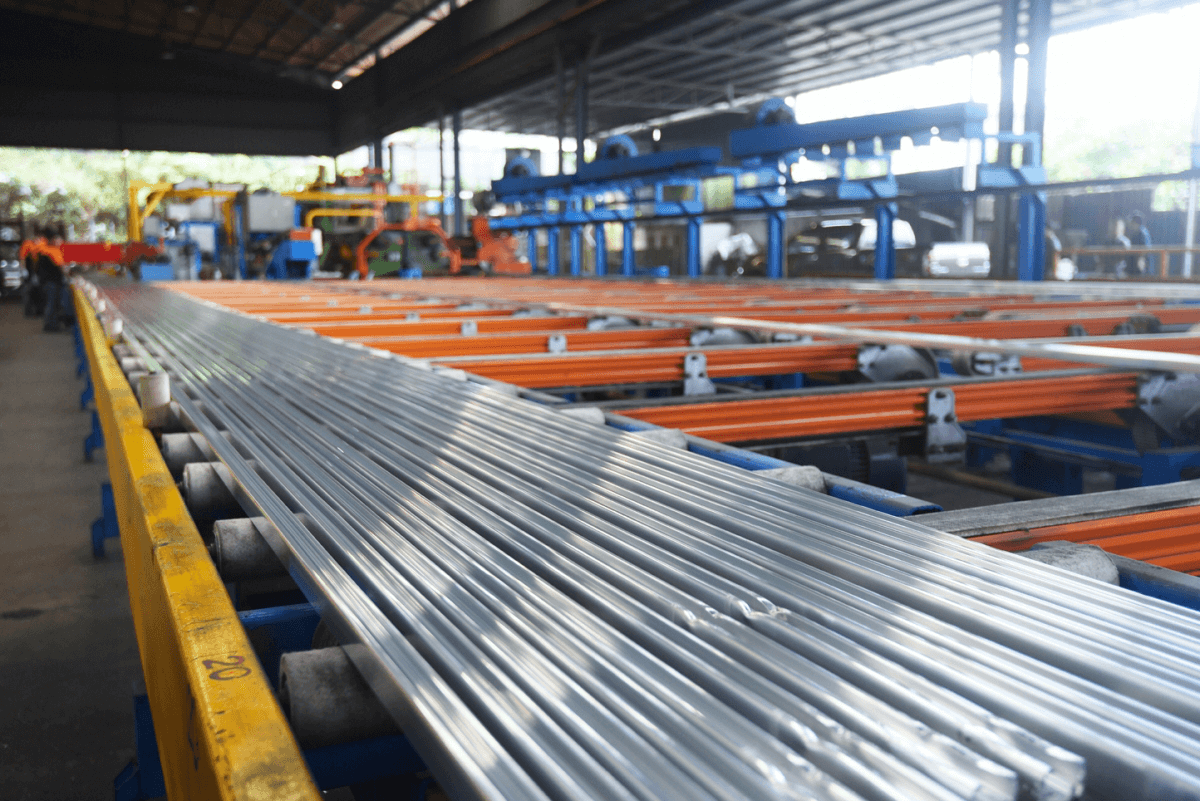

The aluminum extrusion process transforms aluminum alloy into cross sectional products This process has an incredibly wide variety of different applications Aluminum is especially well suited for extrusion as it is uniquely malleable and stable Aluminum Extrusion Design

https://bonnellaluminum.com/tech-info-resources/designing-aluminum-extrusions/

One of the major advantages of aluminum extrusions is that they can be designed in virtually any shape that meets the designer s structural and aesthetic requirements They can be designed to aid in assembly reduce or eliminate forming or welding operations reduce machining requirements and many other purposes

1302 00 Introduction The term extrusion is usually applied to both the process and the product obtained when a hot cylindrical billet of aluminium is pushed through a shaped die forward or direct extrusion see Figure 1302 00 01 The resulting section can be used in long lengths or cut into short parts for use in structures vehicles or Of 10 DESIGN DECISION ADVANTAGES WITH ALUMINUM EXTRUSIONS There are any number of ways in which extruded aluminum can be applied to meet design challenges more effectively more efficiently or more economically than alternative methods of manufacture The following illustrations offer just a few common examples 1

Your first step is to tap the central hole or holes in extrusion A Then you drill a normal hole through extrusion B big enough to get a hex key for your bolt through the hole You thread a bolt