Metal Stamping Design Guidelines The new steels may require new stamping processes This manual briefly covers some of these advanced die process concepts for HSS The manual also provides some guidelines for die design die construction and die tryout

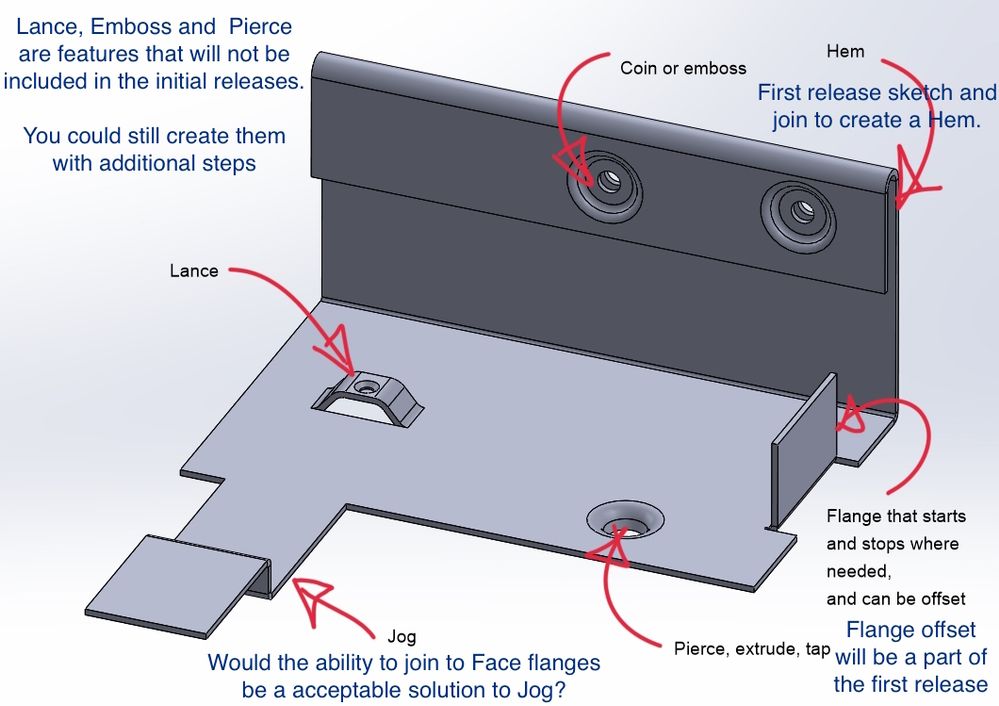

Sheet metal fabrication is the process of forming parts from a metal sheet by punching cutting stamping and bending 3D CAD files are converted into machine code which controls a machine to precisely cut a flat pattern which can be formed into the final part using press brakes and die tools Res Manufacturing engineered stamping solutions takes every possible step to ensure your metal stamped components are designed and manufactured following best practices Holes Minimum hole diameter should be equal to or greater than 1 2 times the material thickness

Metal Stamping Design Guidelines

Metal Stamping Design Guidelines

Metal Stamping Design Guidelines

https://geomiq.com/wp-content/uploads/2019/10/Annotation-2019-10-03-225516-1024x906.png

Industry leaders in metal stamping follow a set of design formulas to ensure they meet a project s requirements in performance aesthetics and most importantly cost Inside ESI s Metal Stamping Design Guide we ve illustrated these metal stamping best practices and highlight tips to incorporate cost cutting considerations into your part

Templates are pre-designed files or files that can be utilized for various purposes. They can save effort and time by providing a ready-made format and design for developing different type of material. Templates can be used for personal or expert projects, such as resumes, invitations, flyers, newsletters, reports, discussions, and more.

Metal Stamping Design Guidelines

Precision Sheet Metal Processing Stamping Part Machine Tools Tools

Following DFM Guidelines For Working With Sheet Metal China Metal

Africa A Arde Referin Sheet Metal Stamping Tolerances Acceptabil

Custom Metal Stamping Dies Ok Billups

Metal Stamping Process

Metal Stamping Design Tips

https://cdn.thomasnet.com/kc/104/doc/ESI-Metal-Stamping-Design-Guide-v7.pdf

METAL STAMPING DESIGN GUIDE Basic design concepts that improve quality and cut costs Introduction Metal stamping is a complex process that can include a number of metal forming processes blanking punching bending and piercing to name a few

https://larsontool.com/wp-content/uploads/2015/06/larson_design_guide.pdf

Metal Stamping Design Guidelines Metal Stamping is an economical way of producing quantities of parts that can have many qualities including strength durability wear resistance good conductive properties and stability

http://www.bokers.com/userfiles/downloads/Bokers_Stamping_Guide.pdf

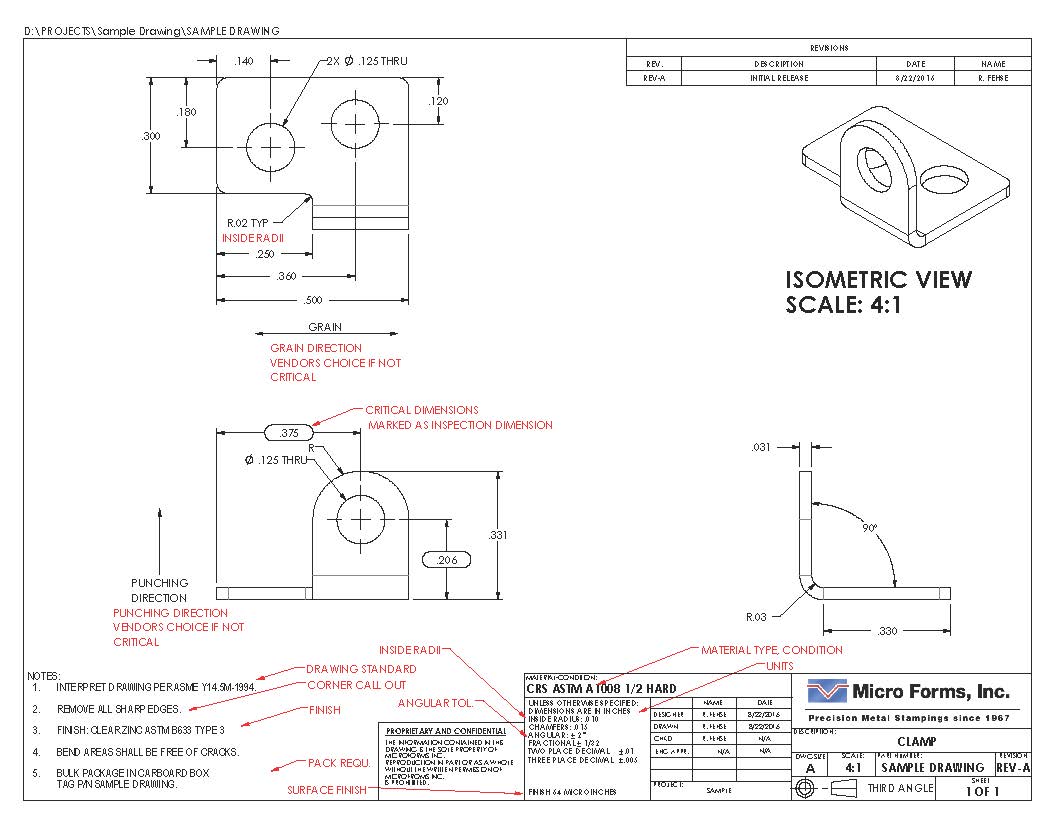

Precision metal stampings are produced by converting flat metal sheet or coil into engineered component parts for manufacturers Parts can be flat and simple or complex profiles Stampings are produced using a variety of punch presses that brings to bear ten to hundreds of tons of stamping pressure onto the sheet or coil

https://www.machinemfg.com/metal-stamping-and-die-design/

The definition of stamping at normal temperature a metal or non metal sheet is pressed on a stamping press machine by a stamping die to cause separation or plastic deformation thereby obtaining parts having a certain shape size and performance From the concept of stamping

https://cdn.thomasnet.com/ccp/30335290/189641.pdf

For a slot or hole 1 diameter then the minimum distance D 2 5T R see fig C Form height to thickness ratio To determine the minimum form height for sheet metal use the following formula D 2 5T R see below The height can be less but it required secondary operations and is far more costly

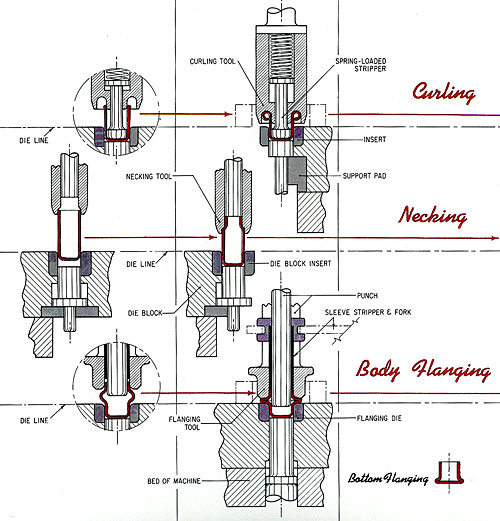

Deep draw is a highly specialized process in metal stamping requiring properly equipped press equipment and engineering expertise Knowing how material e BookDeep Drawn Stamping Design Guide By Neil Fonger Sales Manager 2 The Process Deep drawn stamping refers to the process of forming sheet metal under compressive The draw is designed to prevent the metal from wrinkling as it flows into the cavity Increasing or decreasing the pressure exerted under the pad controls how much metal feeds into the die Oil pans automobile doors and fenders cookware and doorknobs are just a few of the parts manufactured using drawing Coining

Metal Stamping Design Guidelines and Principles Creating a successful stamping requires careful consideration of the part or component design Here are several essential guidelines and principles that must be kept in mind during the designing phase of the project Material Selection