Heat Trace Installation Instructions This manual provides information pertaining to the installation operation testing adjustment and maintenance of the nVent RAYCHEM Elexant 4010i 4020i Heat Tracing Controllers Additional copies of this user manual may be ordered separately through your nVent representative or online at nVent using the document number H60624

HEAT TRACE NELSON CM 2201 CM 2202 HEATTRACE CONTROLLERS Installation and Operating Instructions Table of Contents CM 2201 CM 2202 2018 Nelson Heat Tracing Systems www nelsonheaters GA2497 Rev 6 1 0 Introduction 4 1 1 GettingStarted 2 0 General Application Information 4 The following serves as a guide and overview of the installation startup and operation of a TraceNet TCM2 heat tracing control and monitoring system This guide shall be used in conjunction with the project specific control system drawings and any other standard installation instructions guides provided In the

Heat Trace Installation Instructions

Heat Trace Installation Instructions

Heat Trace Installation Instructions

https://pac-plumbing.com/wp-content/uploads/2020/01/global-electric-heat-tracing-market-scaled.jpg

Pressure rating is a burst pressure and it is rated at a specific temperature Above you can see 370 PSI 23C 73 4F Heat trace on the coldest day of the year to keep the contents of your PVC pipe from freezing will be putting out much more than 73 4F Once you go over that temperature your PSI rating decreases

Templates are pre-designed files or files that can be used for numerous purposes. They can conserve time and effort by offering a ready-made format and layout for creating different sort of content. Templates can be utilized for personal or professional projects, such as resumes, invitations, leaflets, newsletters, reports, presentations, and more.

Heat Trace Installation Instructions

Heat Tracing FORMEX

Heat Tracing Installation By Thermon

How To Install Heat Trace Heat Trace Installation Powerblanket Blog

Electric Heat Tracing Installation Thermon Manufactur Doovi

Electric Heat Tracing System Installation Guide For Petrochemical Plants

Heat Pump Wiring Diagram Database Wiring Diagram Sample

https://www.powerblanket.com/blog/how-to-install-heat-trace/

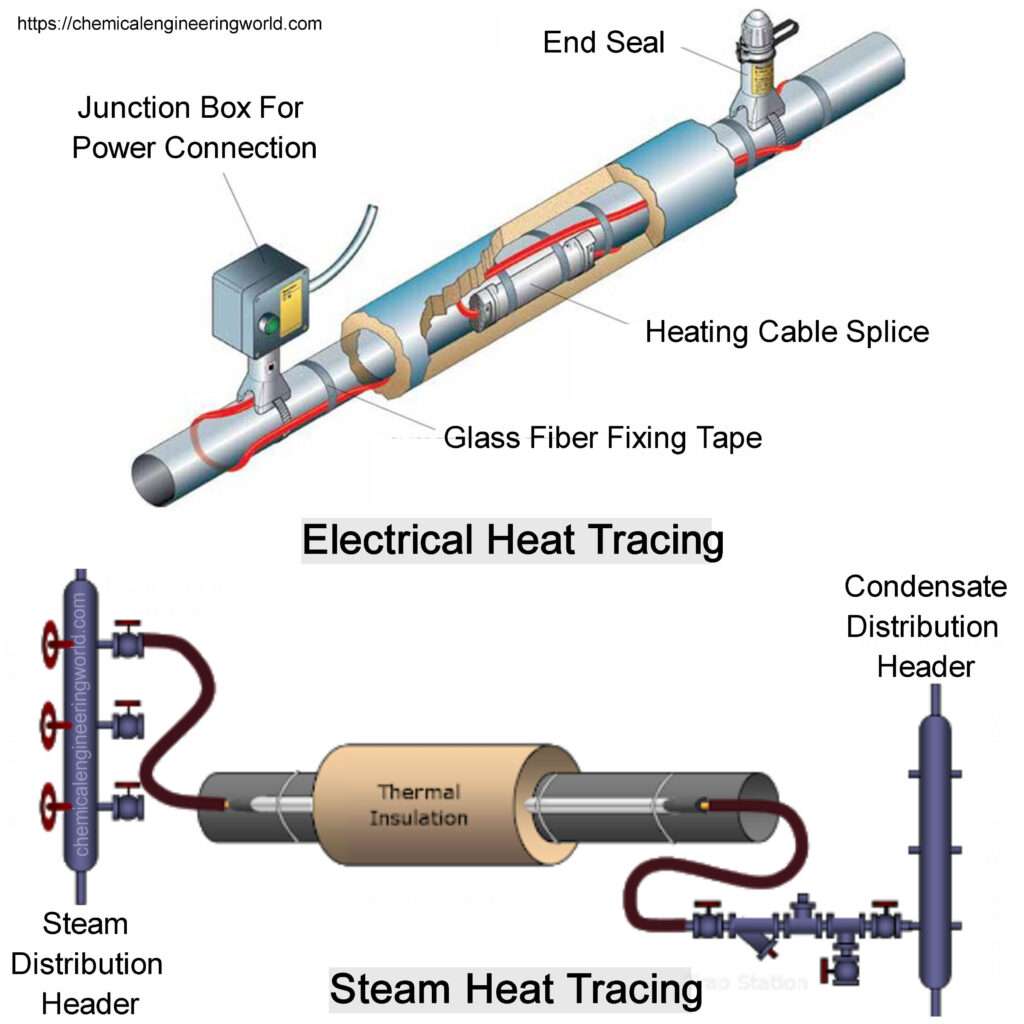

To do so connect the positive lead of the megger to the cable s bus wires and the negative lead of the megger to the cable s braid Again refer to specific system requirements Before making any power connections first make end and splice connections Heat trace can be connected to 120V 208V 240V or 277Vac and to any size breaker

https://www.nvent.com/sites/default/files/acquiadam/assets/RAYCHEM-IM-H57274-SelfRegPowerLimHeatTrac-EN-2304.pdf

1 1 Use of the Manual This installation and maintenance manual is for nVent RAYCHEM Self Regulating and Power Limiting heat tracing systems on thermally insulated pipes and vessels only This includes nVent RAYCHEM BTV HBTV QTVR HQTV XTV HTV KTV VPL heating cables and the appropriate nVent RAYCHEM components

https://go.nvent.com/rs/760-EGW-100/images/Raychem-IM-H57274-SelfRegPowerLimitingHeatTracing-EN_tcm432-26557.pdf

Space and Surface Heating govern the installation of electrical heat tracing systems All heat tracing system installations must be in compliance with these and any other applicable national or local codes 1 4 Warranty and Approvals RAYCHEM heating cables and components are approved for use in hazardous and nonhazardous locations

https://www.valin.com/sites/default/files/asset/document/valin-electric-heat-trace-installation-guide-2021.pdf

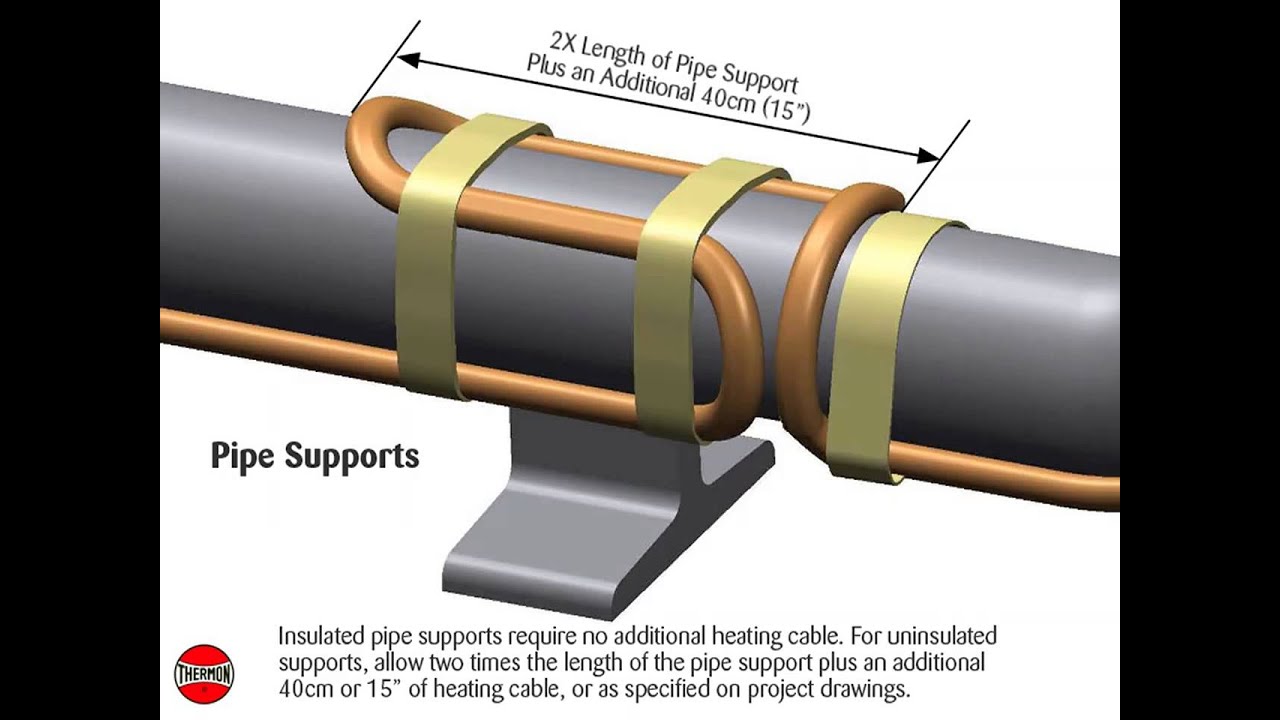

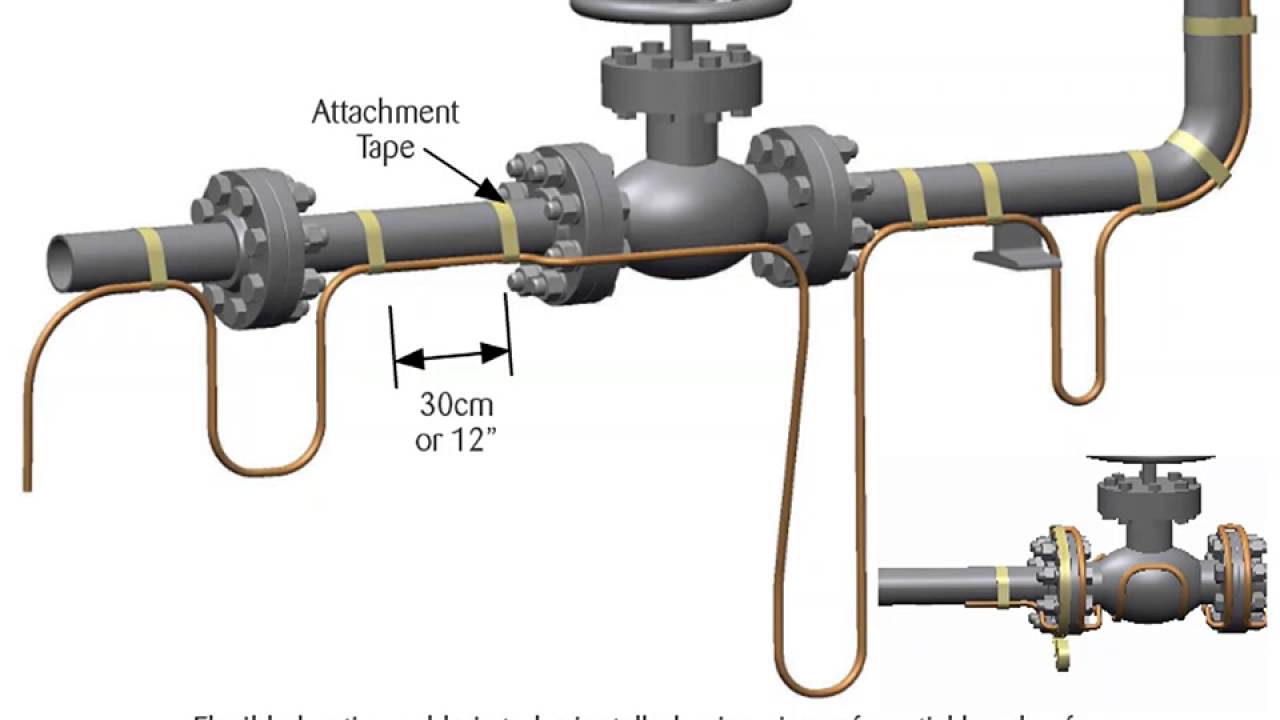

Leave a loop of cable at heat sinks such as valves pipe supports and ange sets Use berglass tape to secure cable to pipe at 18 in 455 mm intervals Fiberglass Tape GT 36 Used to secure trace to the pipe 2 wraps every 2 FOR TECHNICAL SUPPORT CALL 855 737 4718

https://www.nvent.com/sites/default/files/acquiadam_assets/2021-02/RAYCHEM-IM-CDE1547-HeatTracing-EN.pdf

Heat Tracing 1 General information 3 2 Product data 4 3 Heating cable selection 10 4 Heating cable storage 10 5 Product checks 11 Use of the manual The Installation and Maintenance manual is for nVent s Raychem self regulating heating cable systems on thermally insulated pipes For gutters and downpipes

This video will teach you how to professionally install a heat trace Here you can find a list of all product instructions Heat Trace Here you will find our Product Instructions Product Instructions Heat Trace UK based leading manufacturer of electric heat tracing equipment Contact us Heat Trace Ltd Mere s Edge Chester Road Helsby Frodsham Cheshire WA6 0DJ UK 44 0 1928 726451 email protected

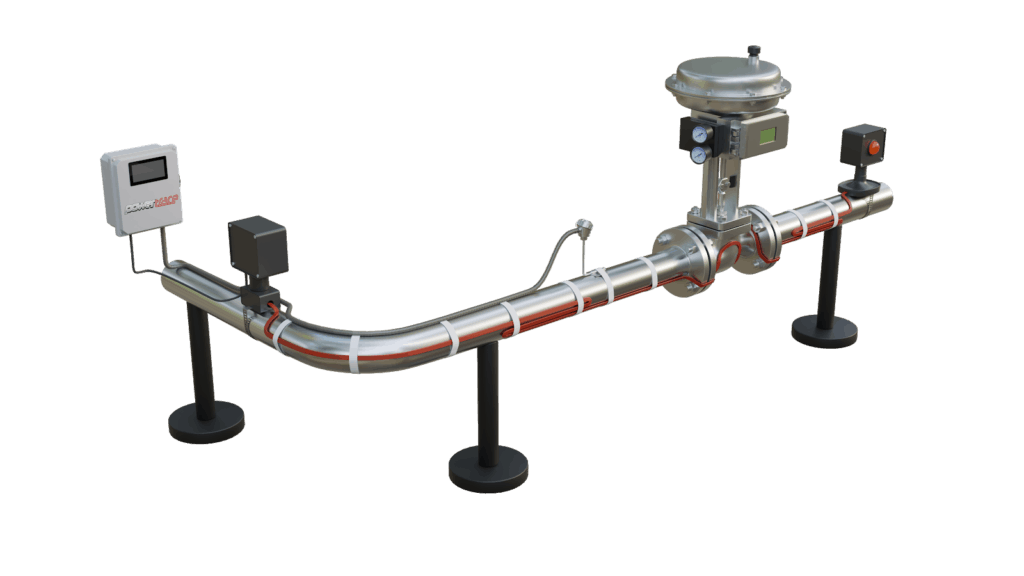

Typical Heat Tracing Installation A complete electric heat tracing system will typically in clude the following components 1 Electric heat tracing cable 2 Power connection kit 3 Control thermostat may be remote ambient sensing control 4 In line T splice kit permits two or three cables to be spliced together 5 Cable end