Heat Staking Design Guide Heat Staking Process Item In caloric pushing or the heated staking process a metal insert is placed inside a pithed or drilled hole which is slightly smaller for the insert This hole will a certain degree of interference also also serve the escort the insertion into location

Heat Staking Design Guidelines Hollow Stake Works well with Large diameter studs no smaller than 080 O D Produces a large strong head Does not have to melt a large amount of material less time less force Avoids sink marks on the opposite side of molded component Brassiere Underwire To heat the ends of 072 inch spring wire spaced 1 2 inch apart uniformly for the application of nylon powder on a 1inch length of the end Inserting Steel Studs into a Plastic Tail Light To heat threaded steel studs for insertion into a plastic tail light assembly at 450 F

Heat Staking Design Guide

https://imgv2-1-f.scribdassets.com/img/document/294641823/original/d5562deb07/1566228966?v=1

Heat staking is a process which utilizes pulsed heat to join two or more parts together where at least one part is made out of plastic It works by heating a plastic part to just above the glass transition temperature while simultaneously applying force so that it is deformed The part is then cooled still under force to complete the process

Templates are pre-designed documents or files that can be utilized for different functions. They can conserve effort and time by offering a ready-made format and layout for creating various type of material. Templates can be used for individual or expert tasks, such as resumes, invites, leaflets, newsletters, reports, presentations, and more.

Heat Staking Design Guide

Induction Heating Heat Staking Machine Gallery

Heat Staking Insert To Plastic YouTube

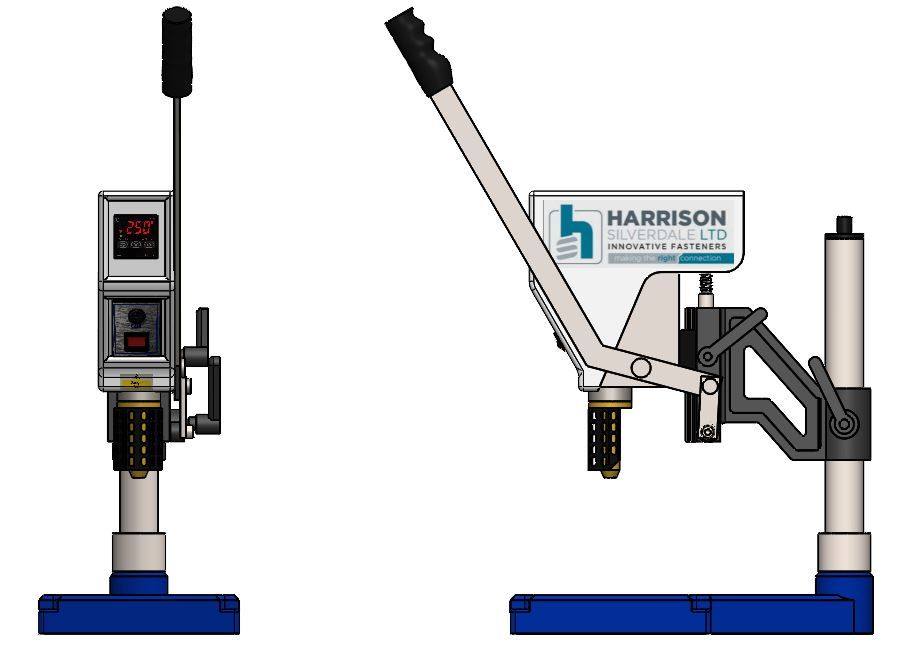

2030MZ Adjustable Heat Staking System Adjustable Heat Staking System

HS1000 Heat Staking Machine At Harrison Silverdale

Oil Or Gas Heating Heat Staking Equipment

Heat Staking Equipment Plastic Assembly Systems

https://www.ambrell.com/hubfs/Ambrell_PDFs/411-0172-10.pdf

Table of Introduction Heat Staking Basic Design Guidelines One of the most common uses for induction heating is the heat staking of threaded metal inserts into plastic Most thermoplastics are too soft to sufficiently hold a thread so brass or steel threaded inserts are added

https://www.amadaweldtech.eu/sites/default/files/documents/whitepapers/AMYE%20Heat%20Stake%20Technical%20document%2003-2016.pdf

Heat Staking is a joining technology to join two or more parts together where at least one is made out of plastic The process is used to melt and deform the plastic material using heat and force at a set process time De forming the plastic is achieved by heating it above the glass transition temperature and apply pressure

https://www.heatstaking.com/design-guidelines/

Design Guidelines No matter which plastic assembly operation you choose proper selection and design of component materials i e stakes joints etc are critical to achieve strong fit for purpose welds Our design guidelines will help optimize your next thermoplastic application

https://www.ambrell.com/blog/the-new-heat-staking-design-guide

Heat staking of threaded metal inserts into plastic also known as metal to plastic insertion is a common induction heating application and this design guide will help you get started With heat staking the insert is preheated with induction and then pressed into a hole in the plastic part

https://solutions.covestro.com/-/media/covestro/solution-center/brands/downloads/imported/1556890495.pdf

Design Guide This manual is intended to help you 17 Ultrasonic Staking 18 Ultrasonic Spot Welding 18 Ultrasonic Inserts Heat Inserts METAL INSERTS 22 Molded In Metal Inserts 22 Coil Threaded Inserts 22 Thread Cutting Inserts 23 Expansion Inserts SNAP AND PRESS FITS 24 Snap Fits

Heat staking can be performed using wide range of thermoplastic materials including polypropylene ABS polycarbonate and many others The integrity of a thermal staked assembly depends greatly upon the geometric relationship between the boss and the thermal tip Proper design will produce optimum strength with minimum flash Heat staking also known as thermoplastic staking is the process of joining two dissimilar materials together In heat staking we use local heating and cooling to raise the temperature of plastic components and allow plastic reforming to be carried out This reforming can be used in a wide variety of applications

Heat staking methods Heat staking applications Which plastics can be riveted Thermoplastics are divided into amorphous and semi crystalline types