Boiler Troubleshooting Guide Pdf F Troubleshooting problems where a Soft Lockout Code is displayed When a soft lockout occurs the boiler will shut down the display will turn red and the Help button will blink Select the blinking Help button to manual 15 Return temp higher than supply

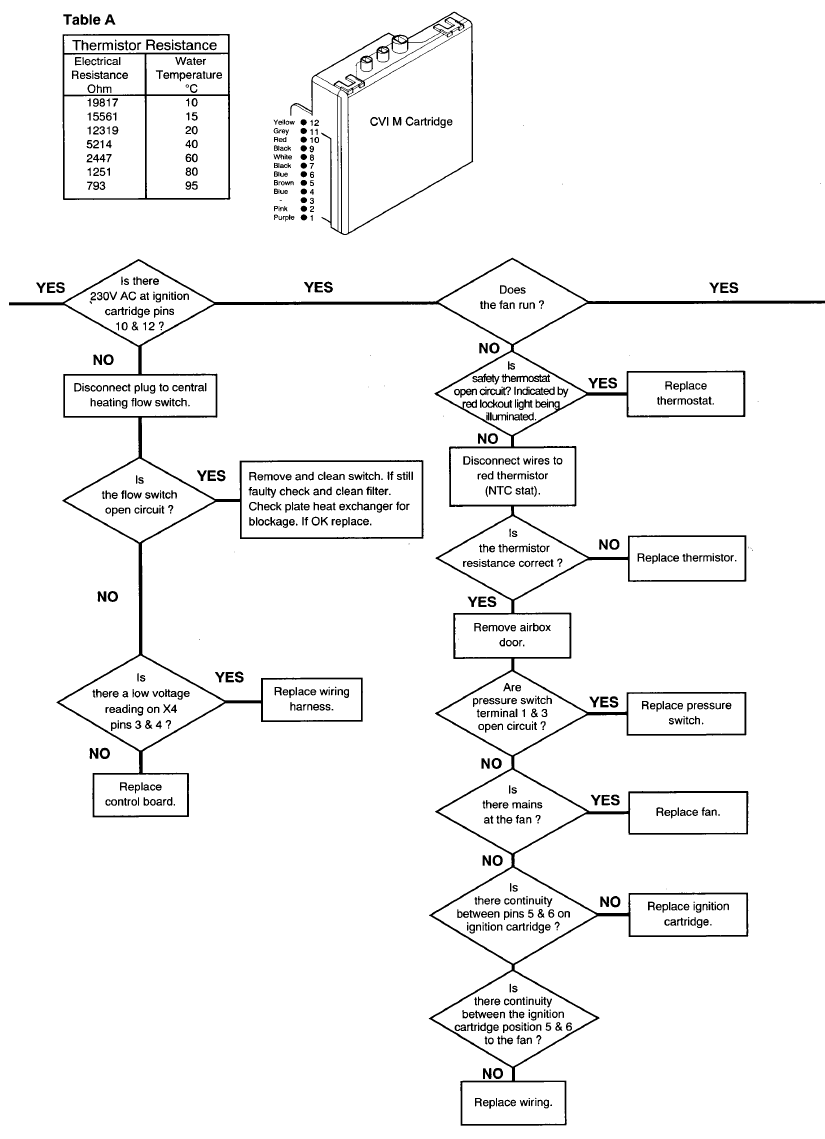

VITODENS 200 Troubleshooting Guide This guide is NOT a substitute for the technical support literature supplied with the Vitodens 200 boiler and the accessories Use in conjunction with Vitodens 200 Quick Start up Guide and Start up Service Instructions Before getting started remember Information and specifi cations outlined in this manual in effect at the time of printing of this manual Manufacturer reserves the right to discontinue change specifi cations or system design at any time without notice and without incurring any obligation whatsoever P N 240008984 Rev A 05 2011

Boiler Troubleshooting Guide Pdf

Boiler Troubleshooting Guide Pdf

Boiler Troubleshooting Guide Pdf

https://f01.justanswer.com/swimcoach83/2014-12-16_022645_furnace_wiring_diagram.jpg

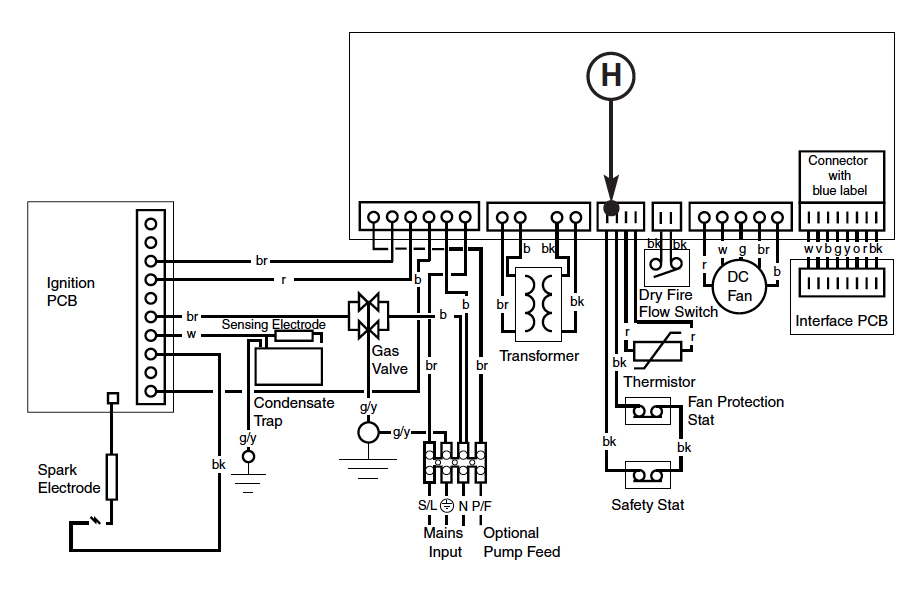

TURN THE TOGGLE SWITCH TO THE R POSITION RESET FOR THREE SECONDS FIG 2 3 AND THEN LET GO THE TOGGLE SWITCH SHOULD GO TO THE WINTER MODE POSITION FIG 2 1 AND ATTEMPT IT S SEQUENCE OF OPERATION PROVIDING THERE IS A CALL FOR HEAT OR DOMESTIC HOT WATER Baxi Luna HT Troubleshooting Guide Baxi Luna HT Troubleshooting Guide

Pre-crafted templates offer a time-saving solution for creating a varied range of files and files. These pre-designed formats and layouts can be made use of for different individual and professional jobs, consisting of resumes, invites, flyers, newsletters, reports, presentations, and more, simplifying the content development process.

Boiler Troubleshooting Guide Pdf

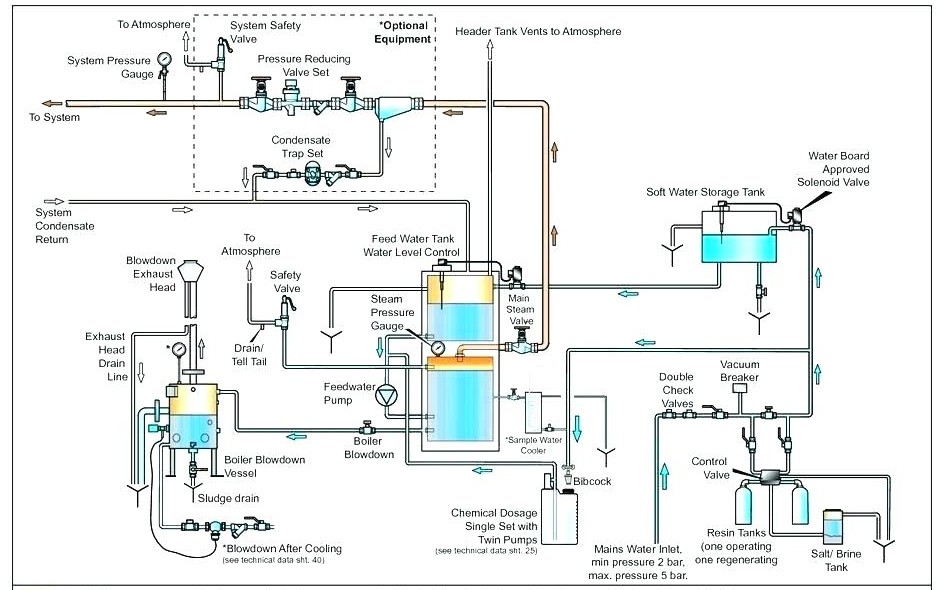

Steam Boiler Replacement In Order To Save System Page 2 Heating

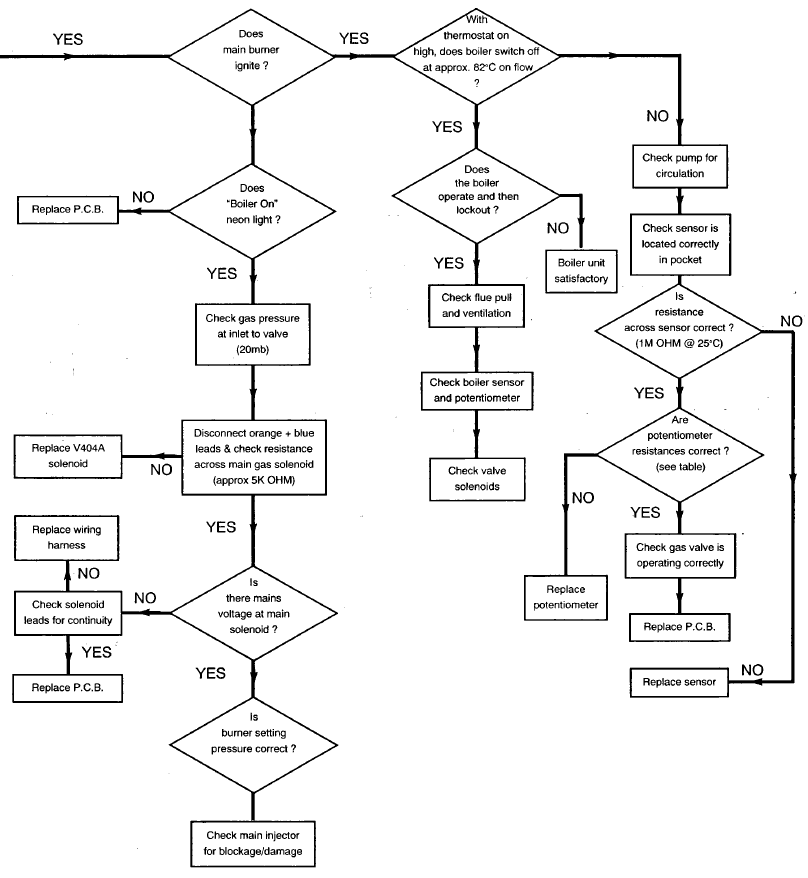

Troubleshooting Guide Boiler Troubleshooting Guide Uk

Boiler Troubleshooting Common Issues How To Fix Boiler Repair

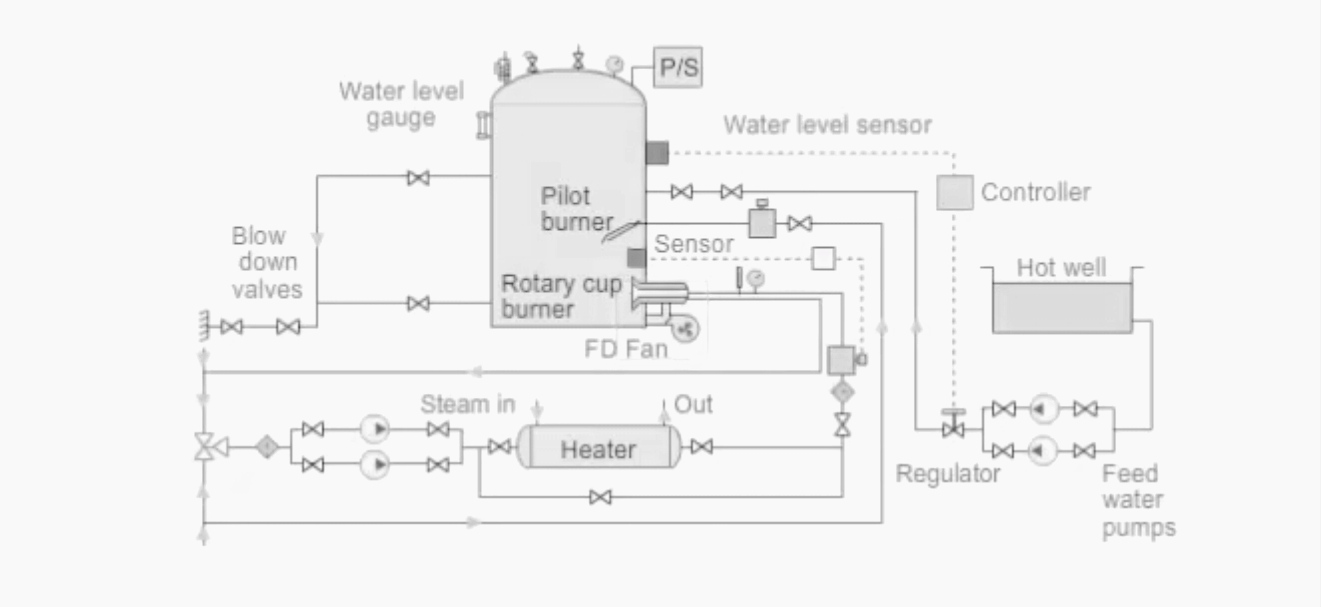

Troubleshooting Boiler Power Plant Instrumentation Forum

Troubleshooting Guide Boiler Troubleshooting Guide Uk

Boiler Troubleshooting Marine Engineers Knowledge

https://www.weil-mclain.com/sites/default/files/field-file/gv90-manual_1.pdf

Boiler Manual Gas Fired Water Boilers This manual must only be used by a qualified heating installer service technician BEFORE installing read Address reported problems 68 Inspect boiler area 68 Inspect boiler interior 68 Inspect condensate drain system 68 nspect all piping for leaks 68

https://www.weil-mclain.com/sites/default/files/field-file/SGO%20Boiler%20Manual%20550141829_0316_WEB%20VERSION%20%283%29.pdf

OIL FIRED NATURAL DRAFT STEAM BOILER SERIES 3 Boiler Manual HOMEOWNER and SERVICE TECHNICIAN read and follow completely Operation SGO with float type low water cutoff 1 If burner does not fire check for Switch on boiler or additional shut off switches turned off Fuses or breaker switch tripped

https://www.boilerdata.com/uploads/7/4/1/4/7414458/boiler-manual-fulton-icx.pdf

ProductBulletin Product Bulletin 2010 001PB The Fulton Companies 972 Centerville Road Pulaski N Y 13142 Date January 22 2010 Subject Water Chemistry Requirements for Fulton Steam Products Products ICS ICX FB A FB F FB S VMP PVLP PHP Electric Steam Boilers and Unfired Steam Generators

https://www.weil-mclain.com/sites/default/files/field-file/cgi-series-2-manual_1.pdf

Boiler must be installed so that gas control system components are protected from dripping or spraying water or rain during operation or service If new boiler will replace existing boiler check for and correct system problems such as 1 System leaks causing oxygen corrosion or section cracks from hard water deposits 2

https://www.lochinvar.com/lit/WBII-SER-Rev%20H.pdf

The webpage provides a service manual for the Lochinvar WBII Series Water Boilers which are designed for high efficiency and low emissions The manual covers installation operation maintenance troubleshooting and replacement parts The webpage also includes a link to a pdf file that contains the manual in full detail

Turn on boiler and allow to come up to at least 10 psig 8 Turn off boiler and allow steam pressure to dissipate to less than 5 psig Allow boiler to sit idle for at least ten minutes 9 Open blowdown valve and drain boiler Turn feed water pump to off position 10 Refill boiler and repeat steps 6 9 What needs to be checked Each of the boiler systems has a number of devices that allow it to function efficiently and safely Common fittings include steam traps pressure gauges insulation pumps and valves To maintain safe and efficient boiler operation these fittings must be maintained properly

BEFORE BEGINNING TROUBLESHOOTING THE BOILER REFER TO THE SERIES PDE INSTALLATION INSTRUCTIONS TO BECOME FAMILIAR WITH THE CONTROLS BOILER SEQUENCE OF OPERATIONS AND WIRING OF CONTROL SYSTEM PRESS THE TEST SWITCH LOCATED ON THE LEFT JACKET PANEL AND NOTE IF ALL 24VAC LIGHTS ARE FUNCTIONAL