Aluminum Die Casting Design Guide In die casting two of your highest cost drivers are the material and the machine time You can reduce the need for both by adding weight saving pockets and thinning your walls Reducing weight and wall thickness in cross sections may seem like an obvious answer Less weight means less material and less material means lower material cost

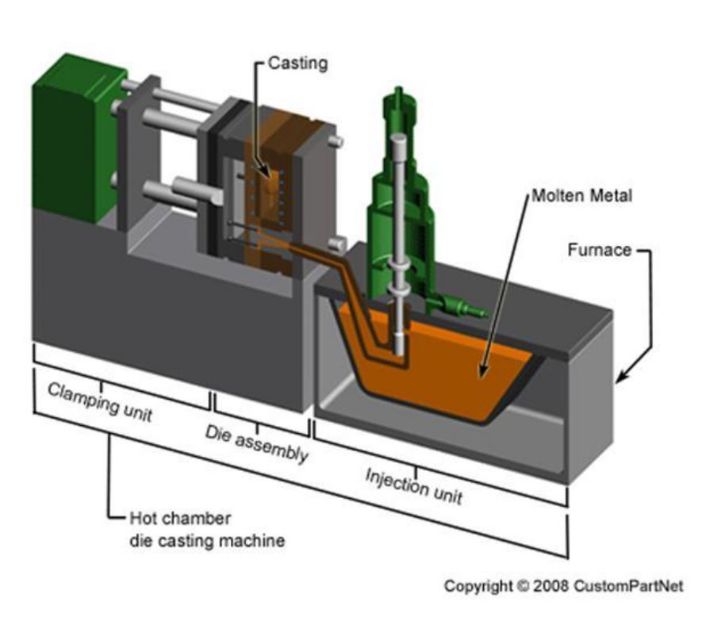

Die Castings Design and Specification Guide Rev 1 9 2017 1 MES Design and Specification Guide Matching Material Properties Pure aluminum is rather weak and malleable on its own But mixed with other metals such as silicon iron Magnesium is the lightest commonly used structural metal Its use in die cast parts has grown dramatically DESIGN GUIDELINES FOR DIE CASTING Die casting is the most widely used solution for creating metal parts with high accuracy and dimensional stability The die casting process relies mainly on process control and optimized parameters to ensure that manufactured parts are defect free and made to specifications Another solution to ensuring design

Aluminum Die Casting Design Guide

Aluminum Die Casting Design Guide

Aluminum Die Casting Design Guide

https://www.sunrise-metal.com/wp-content/uploads/2021/07/The-ultimate-desgin-guide-for-aluminum-die-casting-parts-banner.jpg

Learn regarding best practices for aluminum die casting design Here we offer nine considerations to promote improves manufacturability 1 603 749 1995 USA email protected REQUEST AN FREE QUOTE Aluminum Die Casting Design Guide 9 Considerations for Design Engineers

Templates are pre-designed documents or files that can be used for various functions. They can conserve effort and time by supplying a ready-made format and layout for producing various kinds of content. Templates can be utilized for personal or professional jobs, such as resumes, invites, leaflets, newsletters, reports, presentations, and more.

Aluminum Die Casting Design Guide

Aluminum Die Casting Design Guide 9 Top Considerations

Aluminum Die Casting Design Guide 9 Top Considerations

Die Casting Design And Spec Guide PDF PDF Casting Metalworking

Aluminum Die Casting Design Guide Die Casting Design Guideline

Die Cast Design Aluminum Die Casting Design Guide

Aluminum Die Casting Design Tips DFM Tips For Die Cast Parts aluminum

https://www.cwmdiecast.com/wp-content/uploads/2020/04/Die-Casting-Design-Specification-Guide-2017.pdf

Design Speciication Guide Introduction Recyclable Die Castings and Environmental Practices All of the metal alloys used by CWM are produced from recycled raw materials For example all of the aluminum parts are die cast from post consumer recycled aluminum which meets the requirements of high performance applicaions

https://www.gabrian.com/aluminum-die-casting-design-guide/

Ensure that the part or product will easily come out of the die Minimize the solidification time for a casting Reduce as much as possible the number of secondary operations and Ensure that the final product will perform as required The best way to meet these optimization objectives is to take into account the design considerations

https://www.rapiddirect.com/blog/aluminum-die-casting-design-guide

The recommended wall thickness for aluminum die cast parts ranges from 0 787 in 0 1737 inch However the size is subject to change depending on the part s structure size the material used and application as you could have aluminum die casting components with wall thickness as thin as 0 020 in 3 Parting Line

https://www.dynacast.com/en/knowledge-center/blog/beginners-guide-to-die-casting

For exact tolerances generally between 0 001 and 0 002 is possible for zinc whereas aluminum can hold between 0 002 and 0 004 With achievable draft angles and tolerances in mind you re better equipped to avoid engineering unnecessary cost into the design Too often companies will request exacting tolerances and

https://www.rapiddirect.com/blog/aluminum-die-casting/

Aluminum Die Casting Parts Design 3 Factors to Consider Manufacturers need to take some measures through the aluminum die casting process Mold Design The first big thing is the mold design The design needs to be efficient so you can inject melted aluminum and bring out built parts effortlessly

Learn More Aluminum Die Casting Design Guide 3 How it Compares to Green Sand and Permanent Mold Casting An operator pouring molten metal into a sand cast mold Green sand and permanent mold are two common alternative casting processes to aluminum die casting Green sand processes use wet sand to create the mold for the cast making it less While striving for a reduced wall thickness it s perhaps equal more important to maintain uniformity That will go a long way to ensure a consistently stable repeatable casting that is optimized for manufacturing Get great information about aluminum die pouring design guide and tips toward ensure an success out this metal casting start

According to the NADCA the most popular alloys for die casting belong to the 3xx x series followed by the 4xx x series with alloys from the 5xx x and 2xx x series being somewhat less common but useful for specific applications The following table compares a few of the essential characteristics of popular aluminum alloys used in die casting