Air Compressor Troubleshooting Guide Pdf Air Compressor Manual Models 824254PGT 824254PGTH 82808PGT 82808PGTH 82356VAT 82358VAT 82368VAT 82823GT 82823GTH 821023GT 821023GTH 821330GTK TABLE OF CONTENTS PAGE 8 Troubleshooting Guide 9 Troubleshooting Cont 10 18 Parts Warranty Statement WARNING Safety is a combination of common sense staying alert and knowing how your

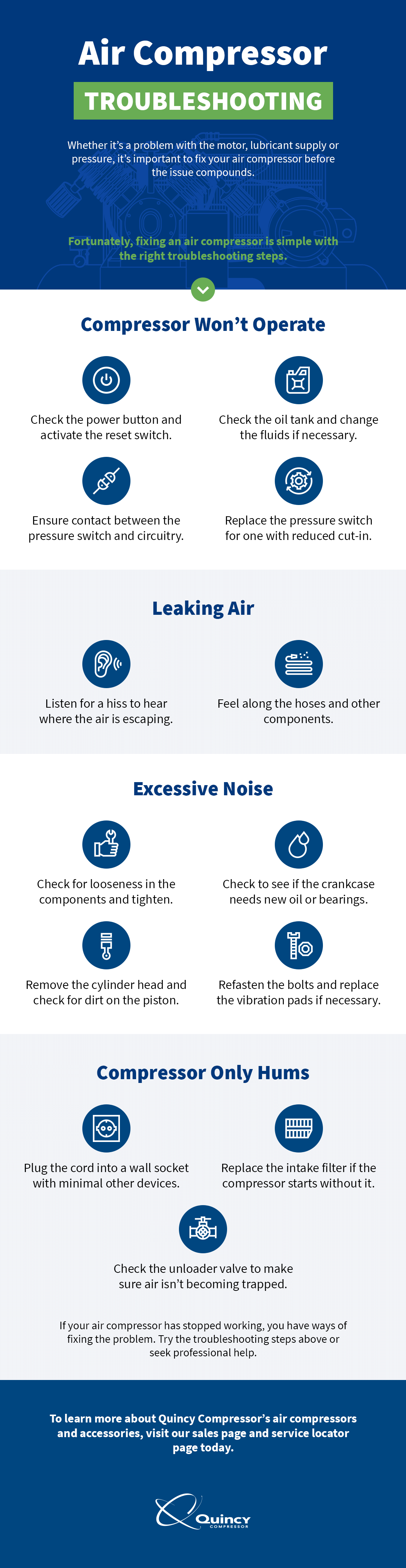

Support If you re experiencing issues with your Atlas Copco stationary air compressor you need a reliable air compressor troubleshooting guide to get it back up and running In this article we ll provide you with expert tips and techniques for troubleshooting Your air compressor unit is suitable for operating air tools caulking guns grease guns sandblasters etc Depending on your application the following accessories may be required An air pressure regulator to adjust the air pressure entering the tool or accessory An air line filter for removal of moisture and oil vapour in compressed

Air Compressor Troubleshooting Guide Pdf

Air Compressor Troubleshooting Guide Pdf

Air Compressor Troubleshooting Guide Pdf

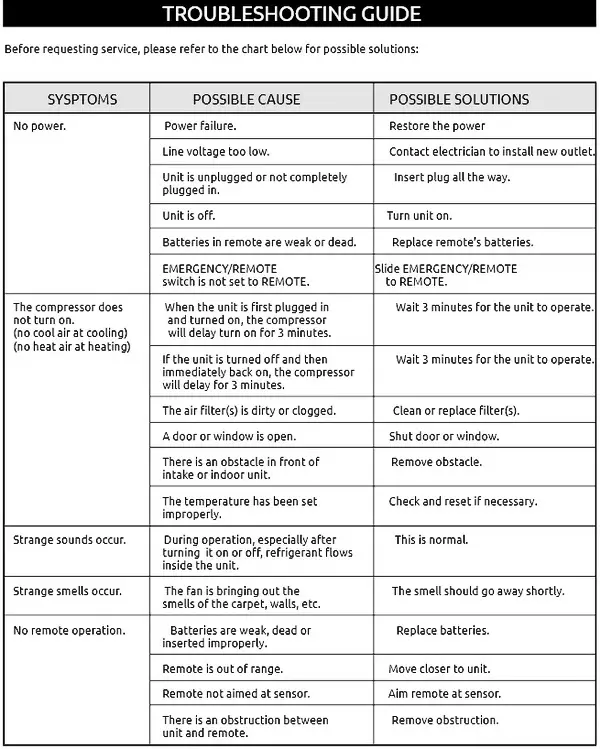

http://removeandreplace.com/wp-content/uploads/2017/06/Daewoo-Split-Air-Conditioner-Troubleshooting-Guide.jpg

Air Compressor Ingersoll Rand CSAXHP1070WCAT Operating Maintenance Manual Code b 59 pages Air Compressor Ingersoll Rand Doosan C185WKUB T2 Export Operation Maintenance Manual 56 pages Air Compressor Ingersoll Rand GHH RAND CG 600 EP belt NON EU Operating Instructions Manual

Templates are pre-designed documents or files that can be used for different purposes. They can save effort and time by providing a ready-made format and layout for developing different type of content. Templates can be utilized for personal or expert projects, such as resumes, invites, flyers, newsletters, reports, presentations, and more.

Air Compressor Troubleshooting Guide Pdf

Piston Air Compressor Troubleshooting Guide Air Tools WA

Air Compressor Troubleshooting Chart

Troubleshooting An Air Compressor That Won s Start Air Compressor

Reciprocating Air Compressors Explained About Air Compressors

6 Simple Steps To Troubleshooting A Compressor KB Delta

Air Compressor Has Broken Down Repair As Soon As Possible House Honeys

https://www.atlascopco.com/content/dam/atlas-copco/local-countries/united-kingdom/documents/Atlas-Copco-Compressed-Air-Manual-8th-edition.pdf

This manual offers a comprehensive guidance to anyone who is looking forward to further explore and get insights in compressed air technology Whether you are a business person manufacturing expert scientist university student or technical consultant we believe that the knowledge collected in the manual will prove very useful to you

https://www.industrialaircompressors.biz/files/943922/uploaded/Air%20Compressor%20RECIP%20Trouble-%20shooting.pdf

20 Compressor valves not functioning properly Motor or engine out of balance Replace compressor valves Balance motor or engine TROUBLE PROBABLE CAUSE Rusty valves and or cylinders 21 Compressor operated too infrequently Compressor does not run long enough to get hot Leaking water jacket or cylinder head

https://www.ccinetwork.com/images/media/Air%20Compressor%20Troubleshooting%20Guide.pdf

AIR COMPRESSOR TROUBLESHOOTING PROBLEM POSSIBLE CAUSE POSSIBLE SOLUTIONS Pressure drop in the tank Air leaks at connections Let the compressor build pressure in the tank to get the maximum pressure if possible Brush soapy water on air connections and look carefully for air bubbles Tighten leaky connections If the problem persists contact

https://www.quincycompressor.com/wp-content/uploads/2020/08/zabatt-compressor-maintenance.pdf

The following are typical recommended minimum maintenance procedures for air cooled reciprocating compressors water cooled double acting reciprocating compressors lubricant injected rotary compressors lubricant free rotary compressors and centrifugal compressors Every 1 000 Hours or 6 Months

https://www.ingersollrand.com/content/published/api/v1.1/assets/CONT4E2E83D68CA740AD96220FDFFCFB9C96/native/oil-less-vandw-two-stage-manual-if3163?channelToken=8b12d6a31ca340d4a7a41afdb250f64d

1 Read all instructions completely before operating air compressor or unit 2 For installation follow all local electrical and safety codes as well as the National Electrical Code NEC and the Occupational Safety and Health Act OSHA 3 Electric motors must be securely and adequately grounded

1 Drain Liquid from the Tank 2 Check and Tighten Fasteners 3 Check and Tighten Electrical Connections 4 Inspect Hoses and Connectors 5 Clean External Components 6 Check Change Air Filters 7 Check Oil Level 8 Change the Oil 9 Change Oil Filter and Air Oil Separator 10 Test Safety Mechanisms 11 Inspect Belts If Applicable 12 Air compressors provide pressurized air to operate tool or instrument air systems Compressors commonly used for this application include reciprocating piston types and rotary types such as centrifugal straight lobe and screw compressors Figure 1 V type Two Stage Double Acting Reciprocating Compressor

Inlet air filter dirty or restriction in the inlet piping to compressor Air system demand is beyond compressor rating Excessive air temperatures to compressor stages Refer to cooling system troubleshooting Dirty impellers worn inlets and or diffusers Contact service professional for assistance